Why Choose TorqLite Hydraulic Wrenches?

-

Engineered for Demanding Industrial Applications

-

Patented Technology for optimal torque accuracy and safety

-

Made in the USA, ISO 9001 Certified and WBENC Certified

-

Catalog with wide range of models: Square Drive, Low Clearance, Jam Nut

-

Fully backed by NIST-traceable calibration and global service support

Explore Our Full Line of Hydraulic and Torque Wrenches

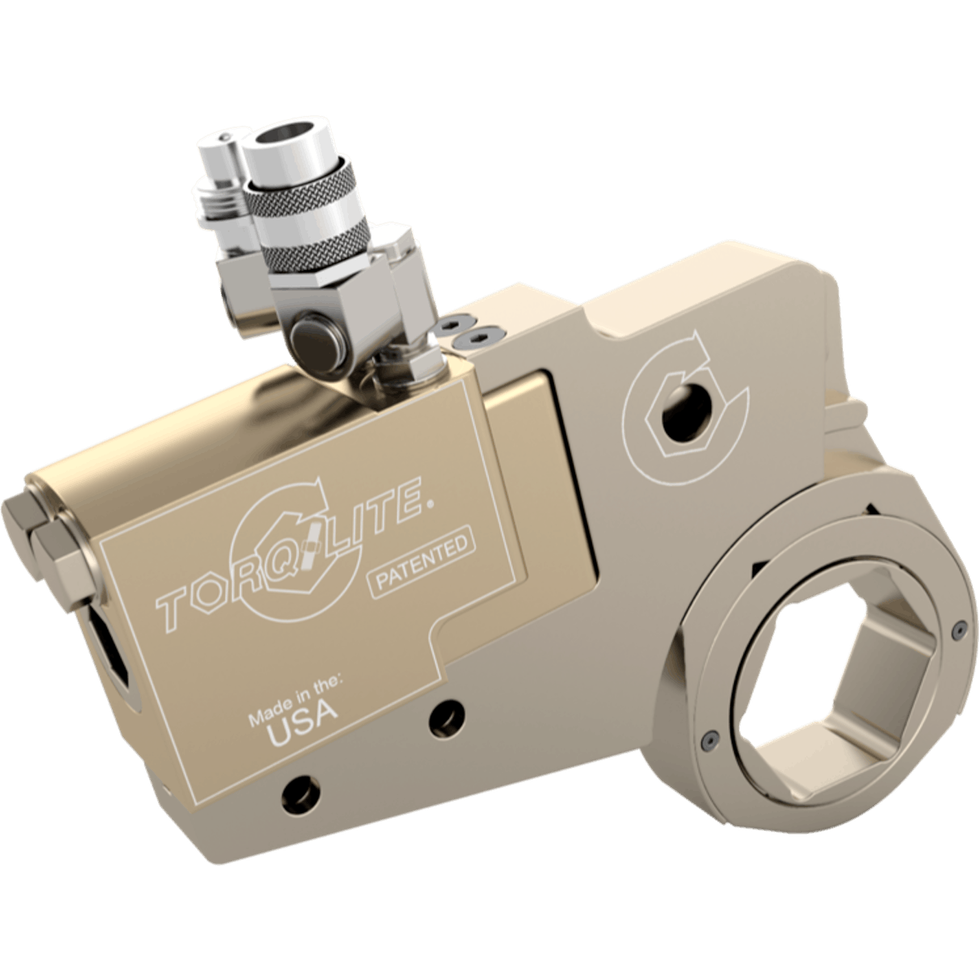

IU‑XL Series – Low Clearance Hydraulic Wrenches

The IU-XL Series is a compact, high-precision low-clearance hydraulic torque wrench specifically designed for bolting applications in restricted or tight spaces. Manufactured using high-strength alloy materials, the IU-XL ensures exceptional durability while delivering consistent, repeatable torque. Ideal for use in refineries, petrochemical plants, and offshore rigs, this tool offers a superior strength-to-size ratio and a patented Freecorner socket profile that extends tool life and enhances safety.

Key Features:

- Available in multiple torque ranges

- High-cycle durability for extended service life

- Lightweight, compact design for confined bolting areas

- Full NIST-traceable calibration included

SU‑XL Series – Square Drive Torque Wrenches

The SU-XL Series is TorqLite’s rugged, reliable square drive hydraulic torque wrench engineered for a wide variety of bolting tasks in industrial applications. With its versatile drive mechanism, this tool effortlessly tightens or loosens heavy-duty fasteners while providing precise, repeatable results. Perfect for pipeline assembly, wind turbine installation, and power plant maintenance.

Key Features:

- Multiple square drive sizes and torque capacities

- Corrosion-resistant, alloy steel construction

- 360° swivel hose fittings for operational flexibility

- Accurate within ±3% of set torque

JN Series – Jam Nut Hydraulic Wrenches

Purpose-built for industrial jam nut applications, the JN Series delivers high torque in challenging, tight-access situations where traditional wrenches won’t fit. Commonly used in power generation, wind energy, and hydraulic press systems, this specialty hydraulic wrench is optimized for precise, safe torque control on jam nut assemblies.

Key Features:

- Precision-fit, slim-line head design

- Robust construction for continuous-duty industrial service

- Compatible with standard hydraulic power consoles

- NIST-traceable certification for assured accuracy

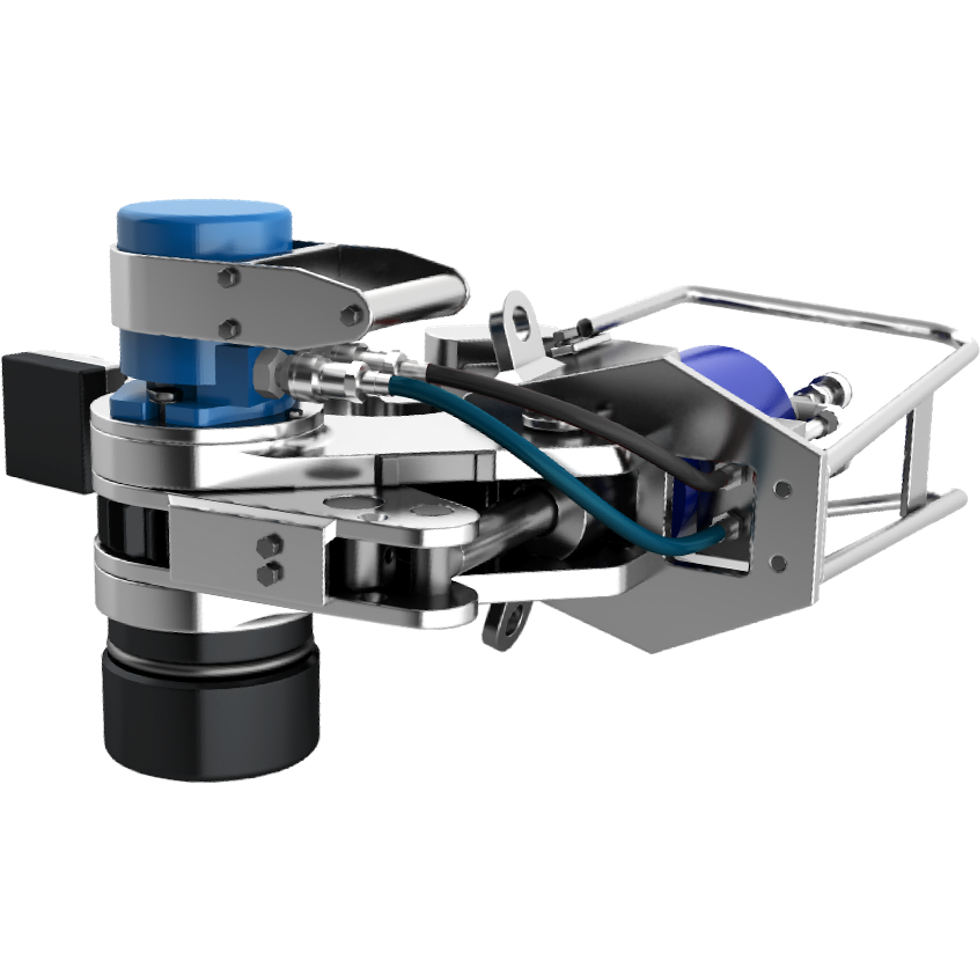

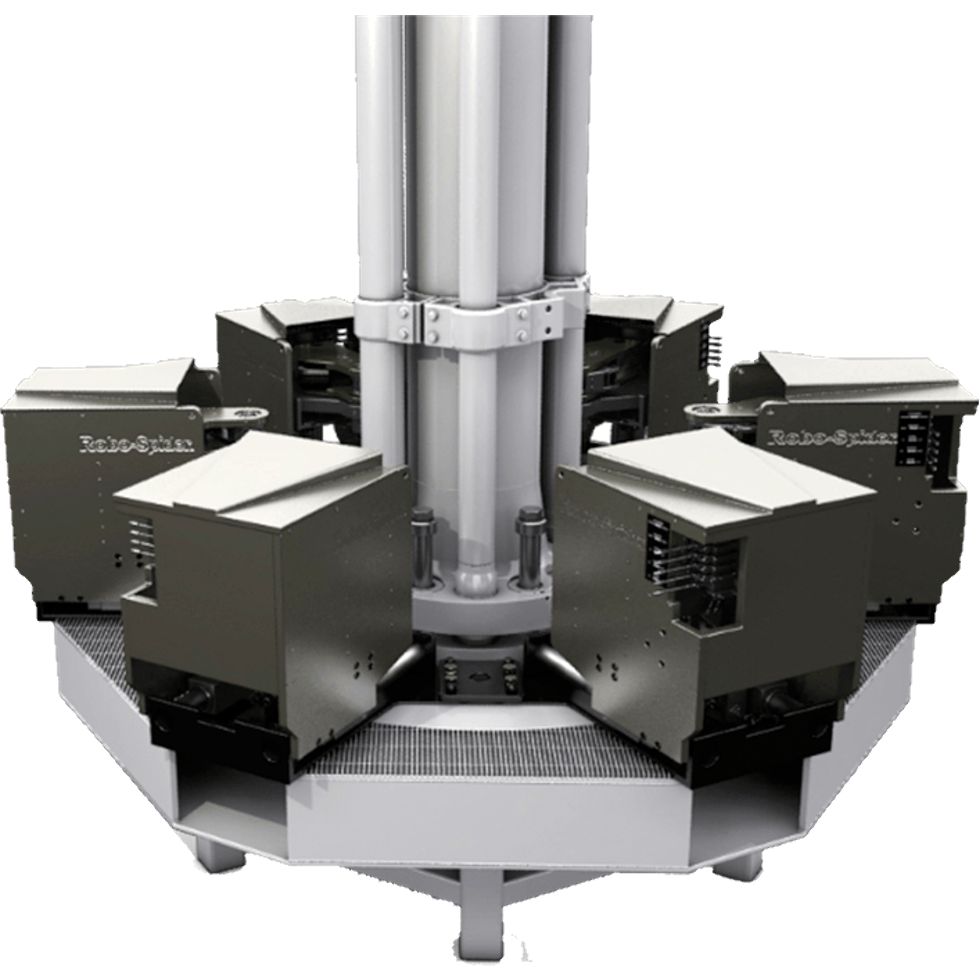

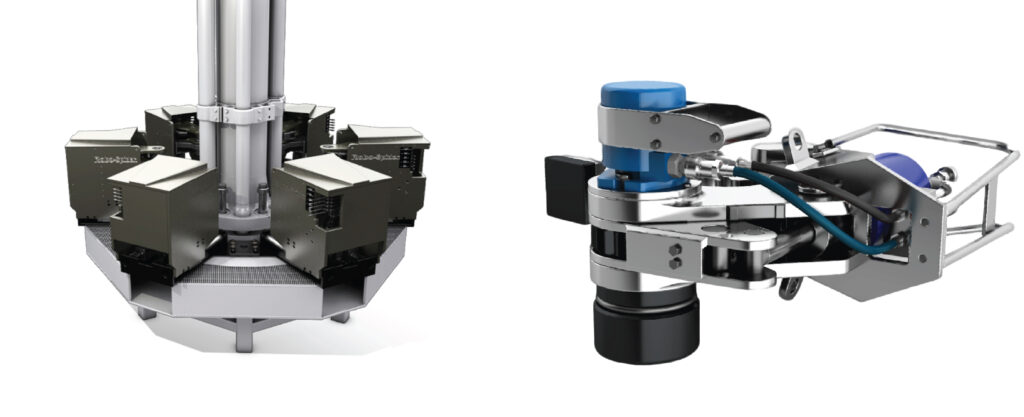

RT Series – Riser Tools and Robo-Spider™ Automated Bolting

The RT Series includes TorqLite’s groundbreaking Riser Tools, designed for riser bolt tensioning and maintenance in offshore and subsea applications. At the forefront of this lineup is the Robo-Spider™, a patented, fully automated hydraulic bolting system capable of torquing six bolts simultaneously. Engineered to improve safety and efficiency during BOP connector and drilling riser make-ups, this system dramatically reduces downtime and manual labor risks.

Key Features:

- Fully automated hydraulic operation

- Synchronized, multi-bolt torque control

- Custom configurations for various riser connector sizes

- Ideal for subsea and topside bolting applications

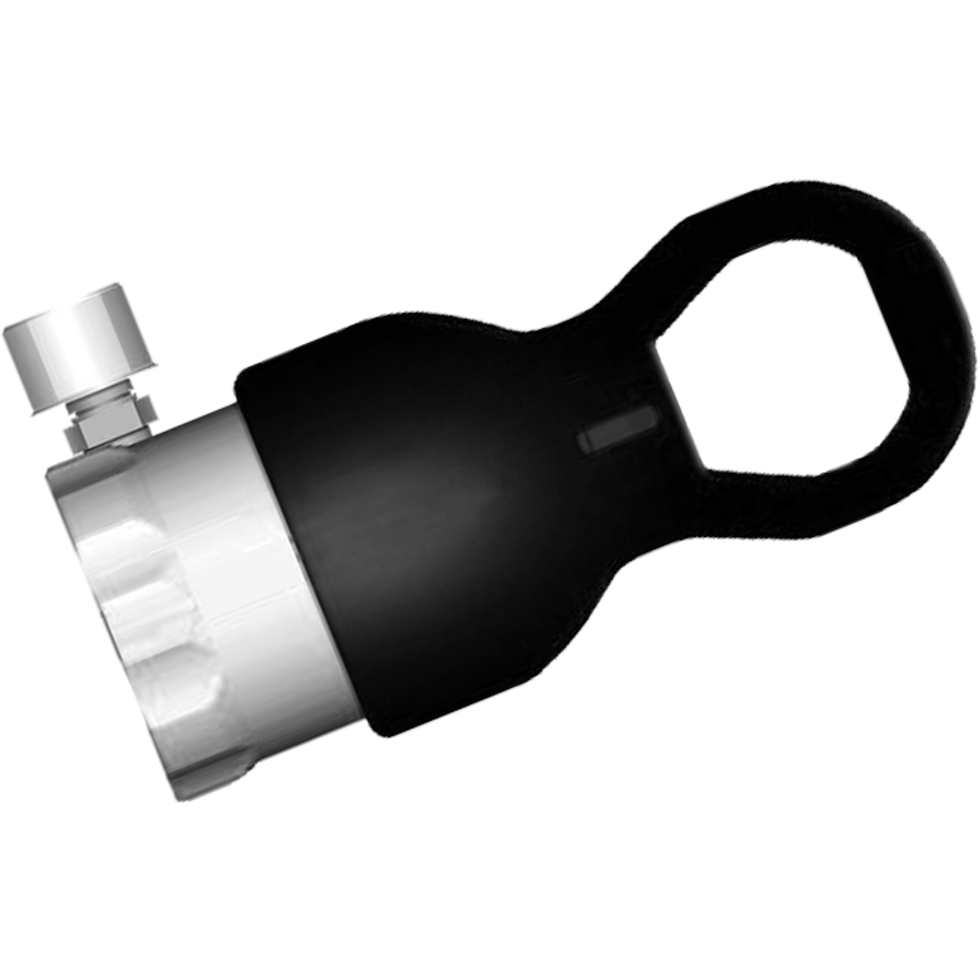

HU Tool – Hammer Union Hydraulic Wrenches

The HU Tool is a specialty hydraulic wrench designed to safely and efficiently tighten or loosen hammer union connections, widely used in oilfield, pipeline, and well service operations. Eliminating the risks associated with hammer blows and manual methods, the HU Tool delivers consistent torque while improving operator safety.

Key Features:

- Rapid, high-torque hydraulic operation

- Custom jaw sizes for various union configurations

- NIST-calibrated for precision

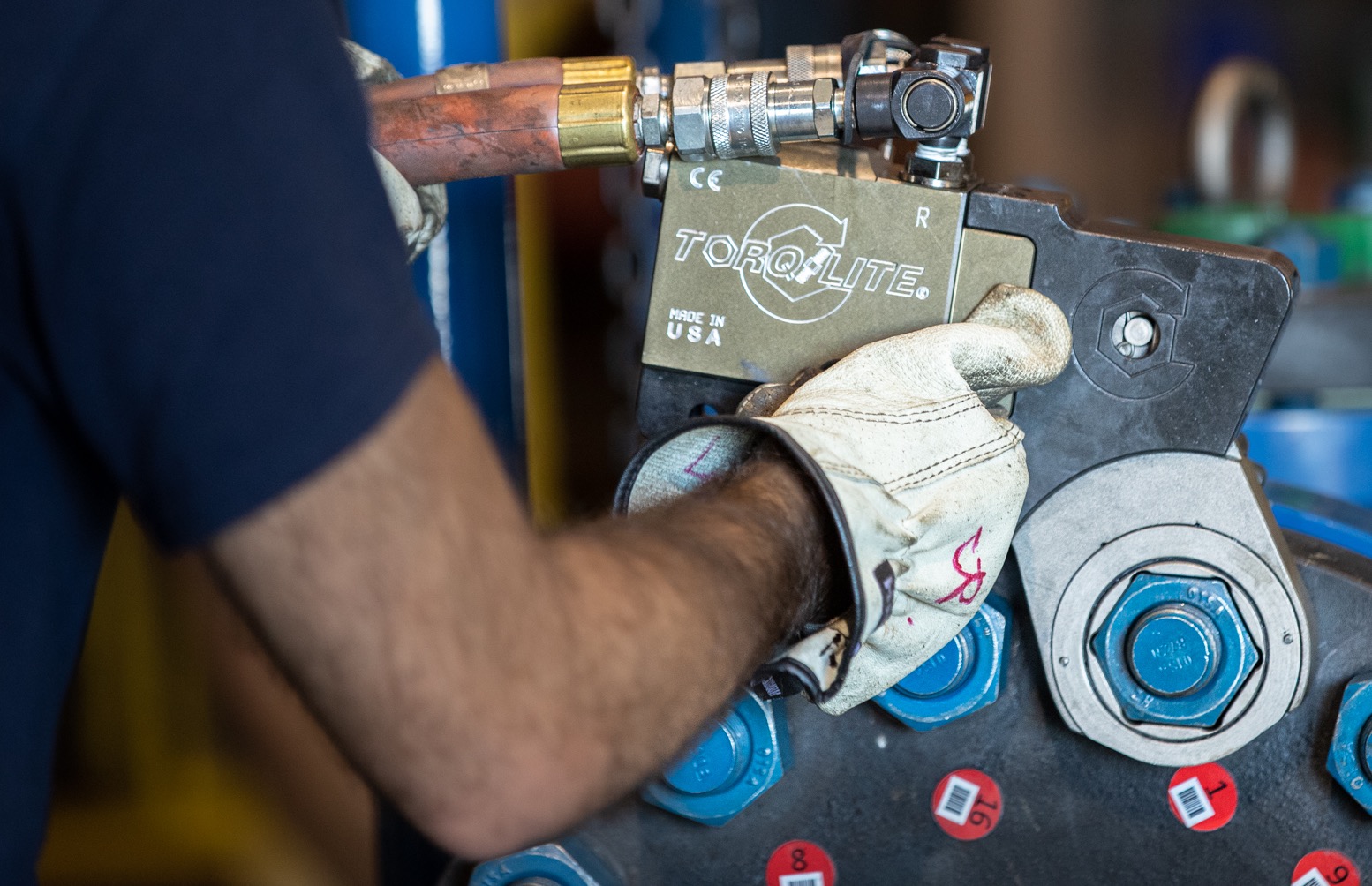

Complete Bolting Solutions for Industrial Projects

TorqLite offers a complete line of industrial bolting systems, including hydraulic wrench set, tensioners, riser tools and specialty accessories. Whether you’re managing pipeline maintenance, refinery shutdowns, or wind farm assembly, our torque solutions improve productivity, accuracy, and on-site safety.

What Torqlite's Customers Say:

"Torq-Lite worked for us as a subcontractor and we were very pleased with all aspects of their operations. David Hensley communicated Torq-Lite’s plan on the project and his team executed the plan effectively. We enjoyed working with Torq-Lite and would do so again."

"TorqLite is an excellent company. They were vital in providing solutions to my company’s problems."

Request a Quote for Hydraulic Wrenches

Ready to upgrade your bolting systems? Connect with our team for a custom quote on hydraulic wrenches and industrial torque wrenches tailored to your project requirements.

Contact Info:

Frequently Asked Questions (FAQs)

A hydraulic wrench is a high-powered, precision tool used to apply controlled torque to fasteners, such as bolts and nuts, in industrial applications. Unlike manual or pneumatic wrenches, a hydraulic wrench uses pressurized hydraulic fluid to drive a piston, which then turns a ratcheting mechanism connected to a drive or hex link. This allows for exceptionally high torque output with precise, repeatable accuracy — often required in industries like oil and gas, power generation, wind energy, and heavy construction.

TorqLite’s hydraulic torque wrenches are calibrated to deliver exact torque specifications within ±3% accuracy, making them essential for applications where improper bolt tension could lead to safety hazards, equipment failure, or operational downtime.

TorqLite manufactures a comprehensive range of hydraulic wrenches and industrial torque wrenches designed to meet the demands of various industries and applications. Our product line includes:

- IU-XL Series Low Clearance Hydraulic Wrenches for tight-space bolting

- SU-XL Series Square Drive Torque Wrenches for general-purpose industrial use

- JN Series Jam Nut Wrenches for power generation and hydraulic systems

- RT Series Riser Tools including the automated Robo-Spider™ for riser bolting

- HU Tool Hammer Union Wrenches for oilfield operations

- Bolt Tensioners for both topside and subsea bolting projects

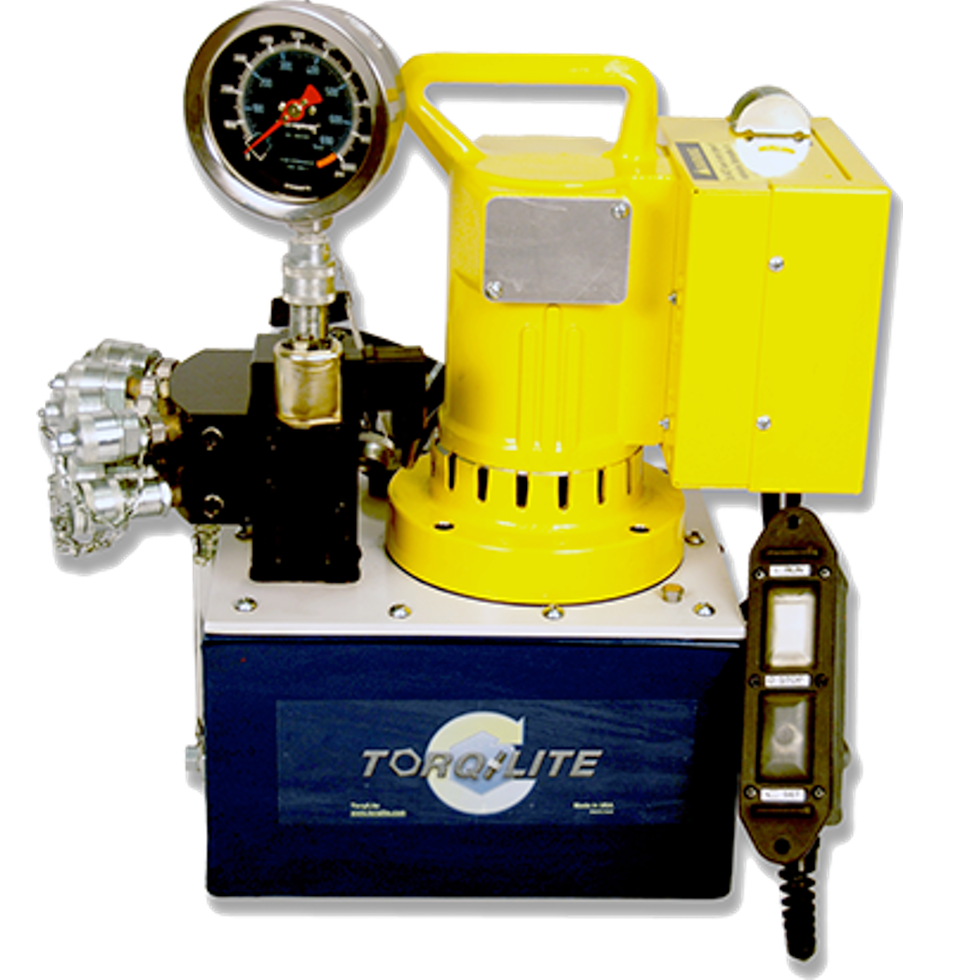

- Hydraulic Power Consoles and Pumps for powering all torque tools

- Backup Wrenches, Sockets, Nut Cutters, and Accessories

Each of these tools is designed with durability, safety, and accuracy in mind, and all come with NIST-traceable calibration certificates.

Choosing the correct hydraulic torque wrench depends on several critical factors:

- Torque Requirement: Determine the maximum and minimum torque needed for your fasteners.

- Clearance Constraints: Assess the available space around the bolt. For tight spaces, a low clearance hydraulic wrench like the IU-XL Series is ideal.

- Drive Type: Decide between square drive wrenches for versatility and hex link wrenches for low-profile applications.

- Application Environment: Consider environmental factors like subsea, offshore, or hazardous conditions, which may require specialized coatings or corrosion-resistant designs.

- Power Source: Ensure compatibility between your torque tool and hydraulic power console, available in electric, air or manual configurations.

TorqLite’s experienced technical team can assist you in selecting the right industrial torque wrench and accessory package tailored to your specific jobsite and operational requirements.

Yes — every TorqLite hydraulic wrench and torque wrench is manufactured to the highest standards and comes with a NIST-traceable calibration certificate. Additionally, TorqLite operates under ISO 9001 certification, ensuring consistent quality control and precision manufacturing processes. Many of our tools are also CE certified for global industrial use, including applications in oil and gas, wind energy, mining, and power generation sectors.

Our tools continue to undergo rigorous testing and calibration both during production and before delivery, guaranteeing ±3% torque accuracy and ±1% repeatability, making them trusted by industry leaders worldwide for safety-critical bolting tasks.

In addition to manufacturing a full line of hydraulic torque wrenches and industrial bolting systems, TorqLite offers comprehensive services to support the longevity and performance of your equipment:

- Tool Calibration & Certification: NIST-traceable calibration for torque wrenches ranging from 1,000 to 50,000 ft-lbs.

- On-Site Bolting Services: Including riser maintenance, hydraulic tensioning and bolt torquing for critical industrial projects.

- Warranty Programs: Extended warranties covering tool calibration, parts and labor.

- Equipment Leasing & Rental: Short-term and long-term hydraulic tool leasing options.

- Global Distribution & Service Centers: Worldwide sales and technical support network.

- Custom Tool Engineering: Bespoke torque and tensioning tools designed for unique or challenging applications.

These services ensure maximum uptime, compliance, and operational safety for clients in industries like offshore drilling, power generation, and petrochemical refining.