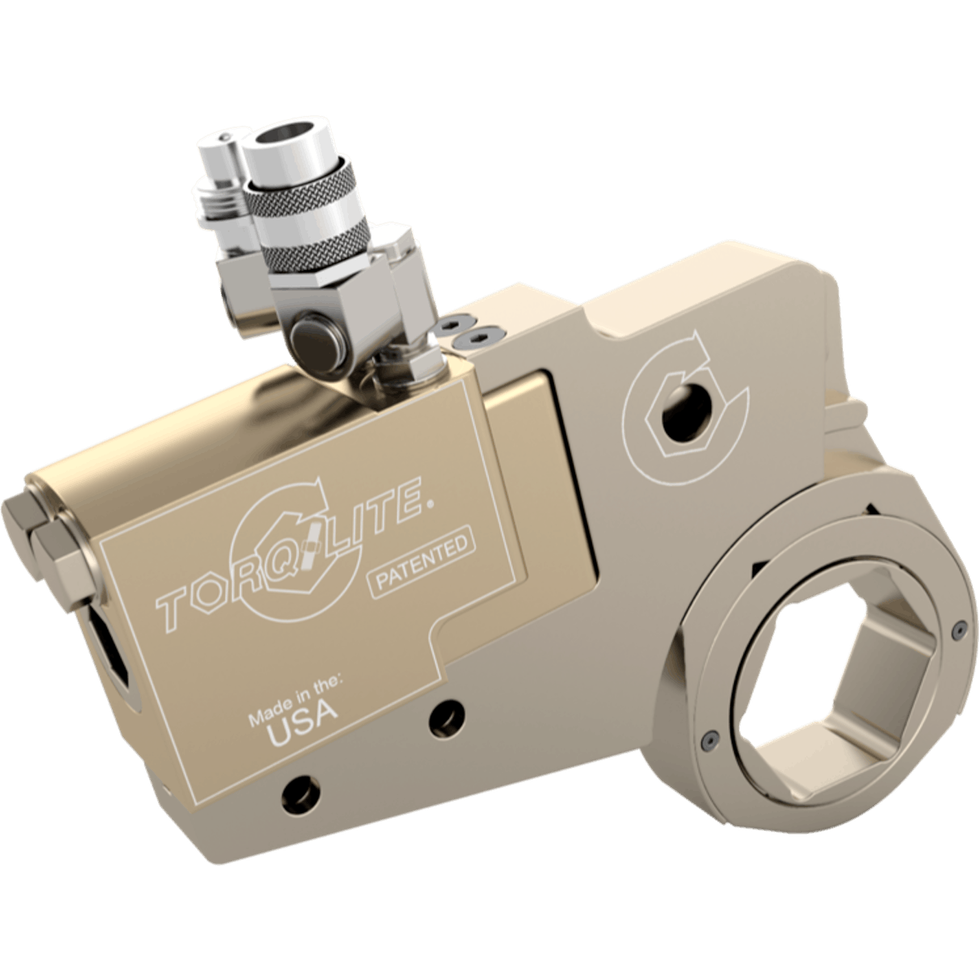

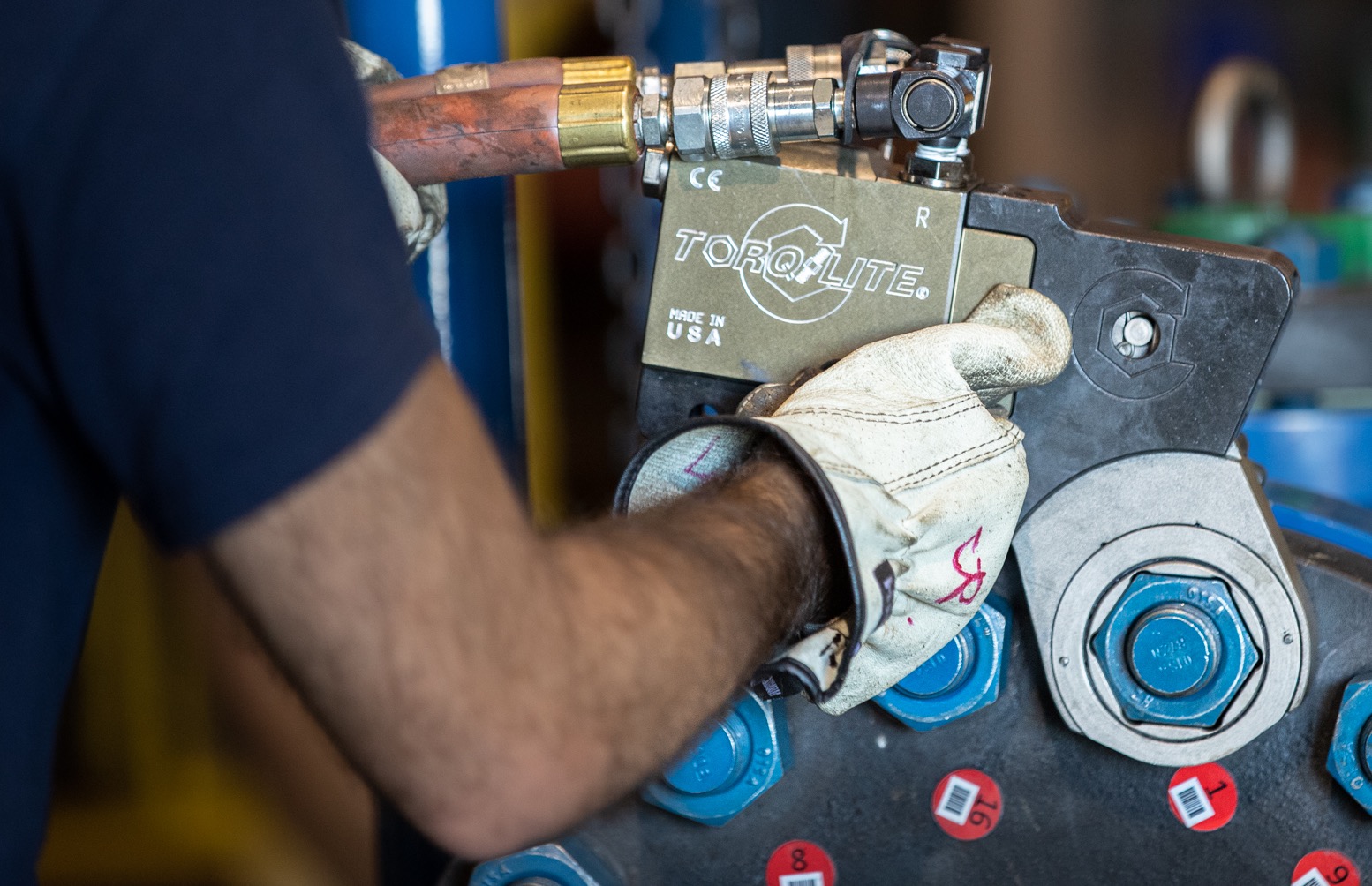

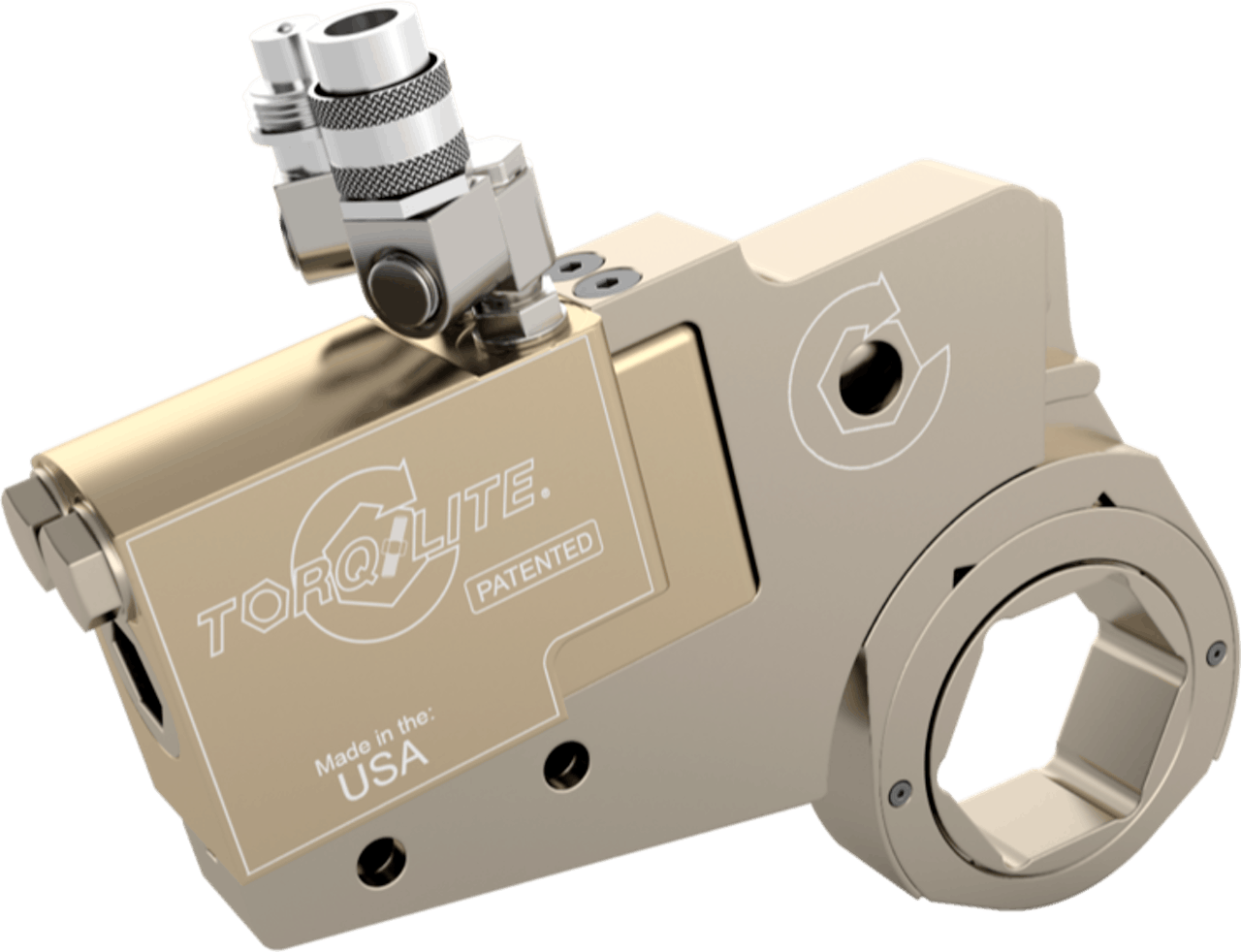

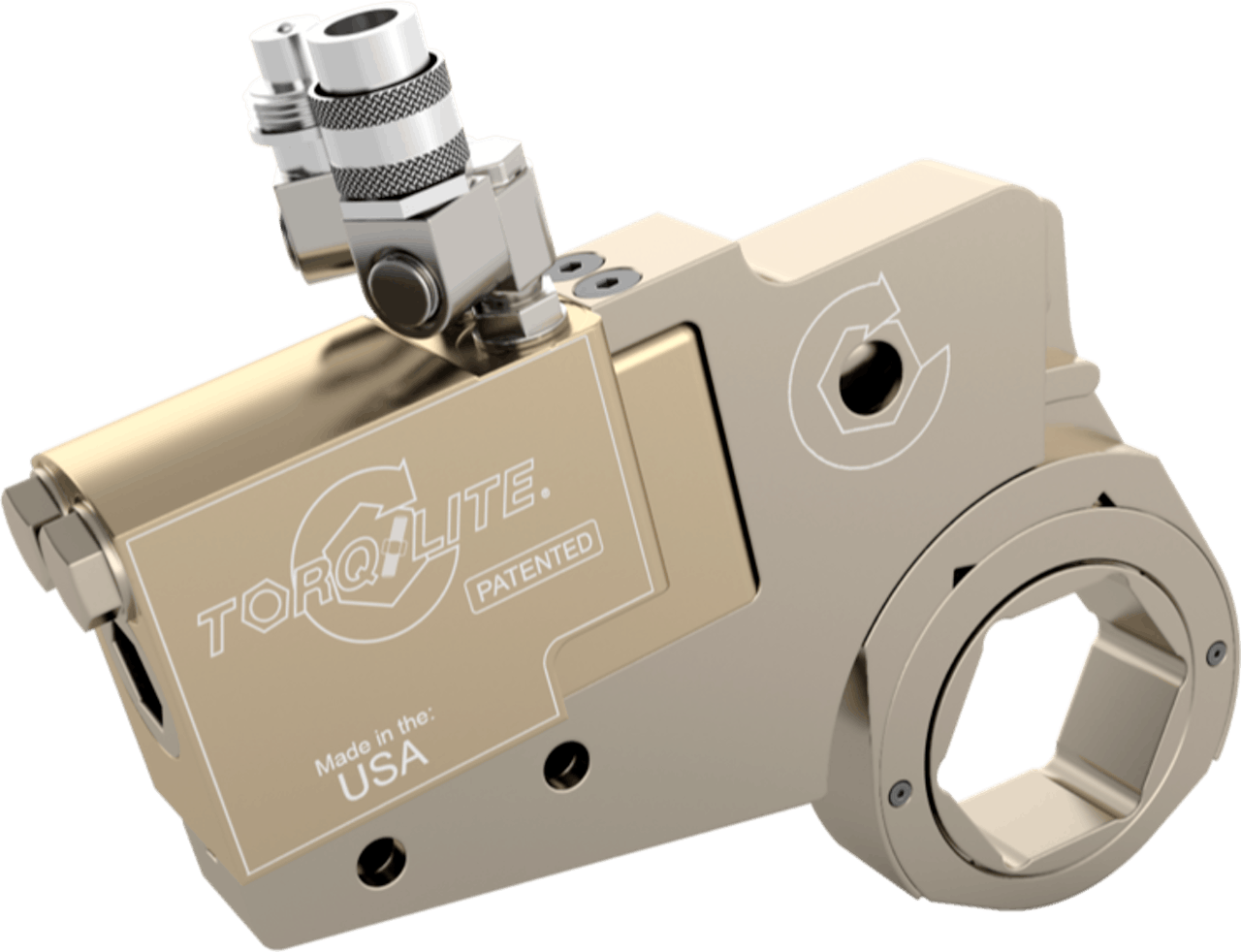

Our innovative, low-clearance wrench can fit just about anywhere, a perfect tool for every job.

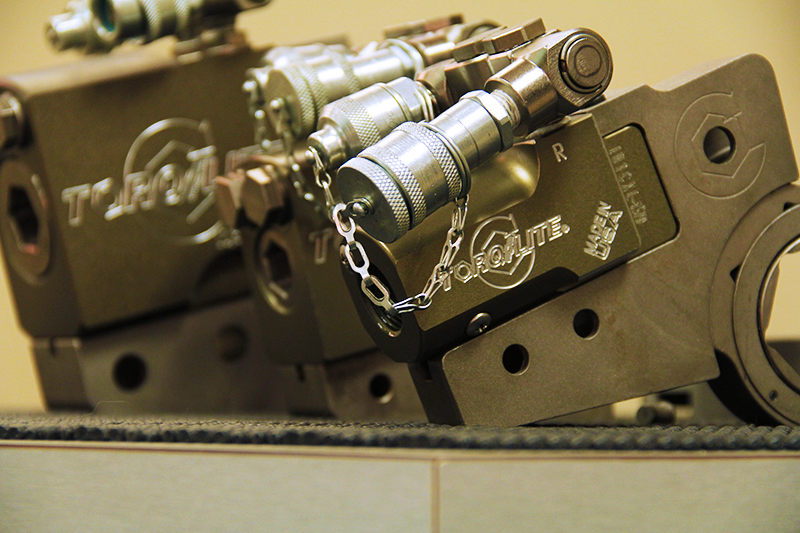

The patented inline-ratcheting design combines the cylinder and the body together in one unit, so changing the head is all that's required when switching sizes. This gives you the ability to use one body & cylinder unit for a wider range of nut sizes, simplifying your operation and saving you money.

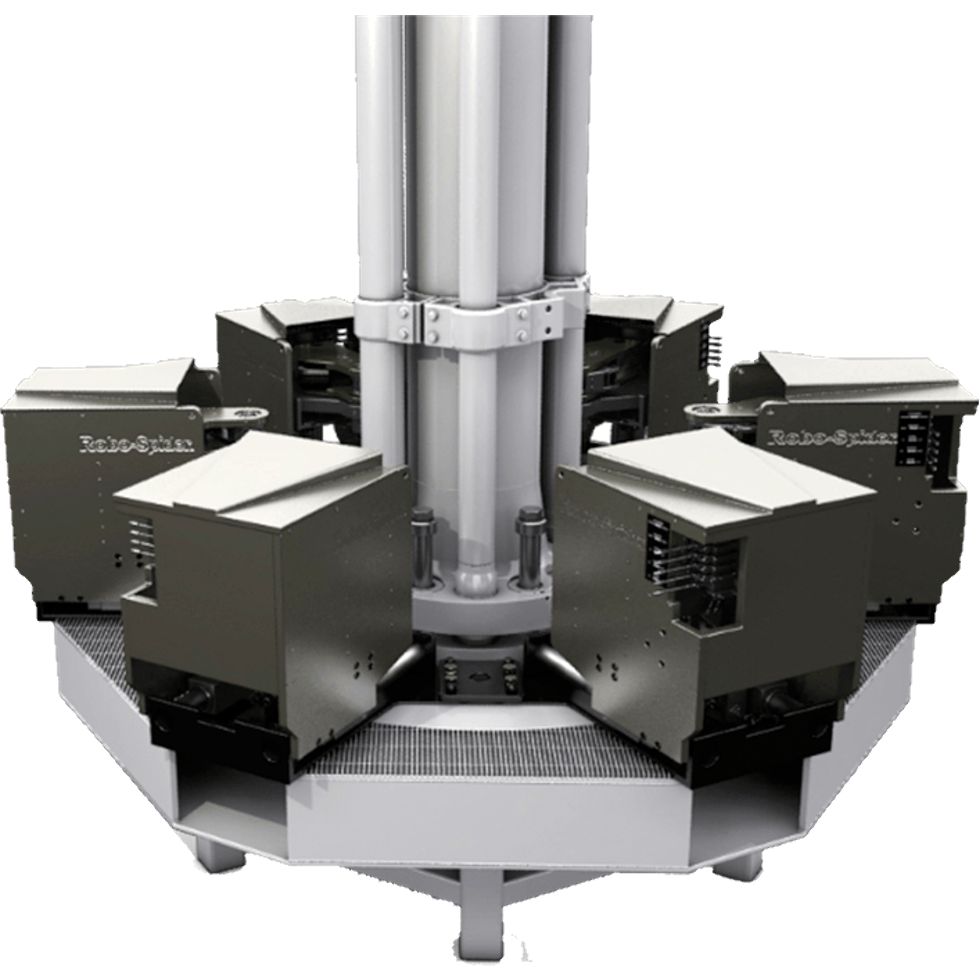

Our wrench is versatile, durable, and all that you need to get the job done.

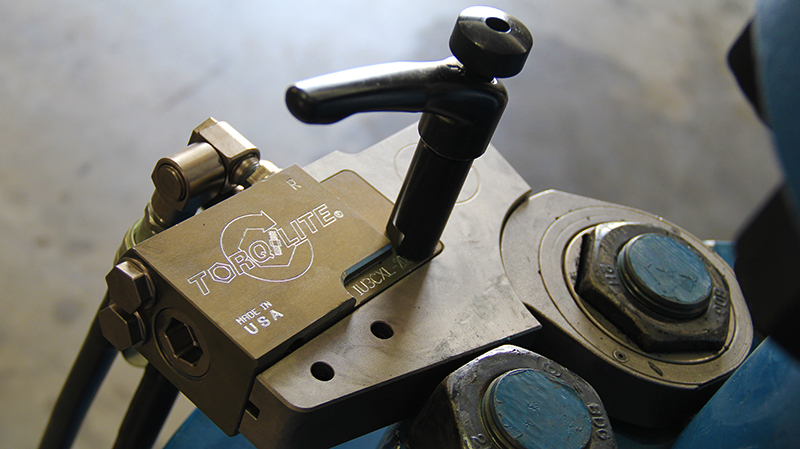

IU-XL Series (Low Clearance)

The ultimate Low-Clearance Wrench product.

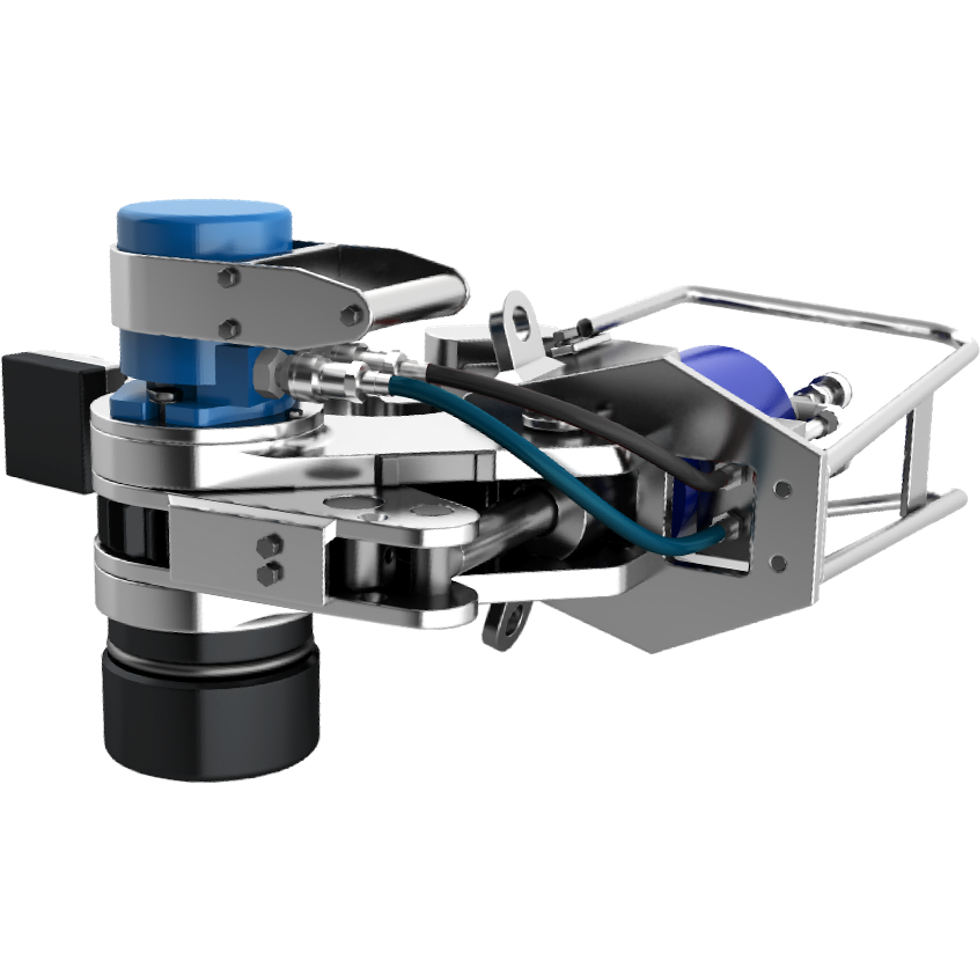

- Practical Body Design This low-clearance industrial torque wrench is designed with a super-low profile ensuring that it can fit just about anywhere.

- Full rotation swivels Our patented 360º swivels rotate on both axes, giving you enhanced control and maneuverability.

- Superior functionality The cylinder and the body are together in one unit, so changing the head is all that's required when switching sizes.

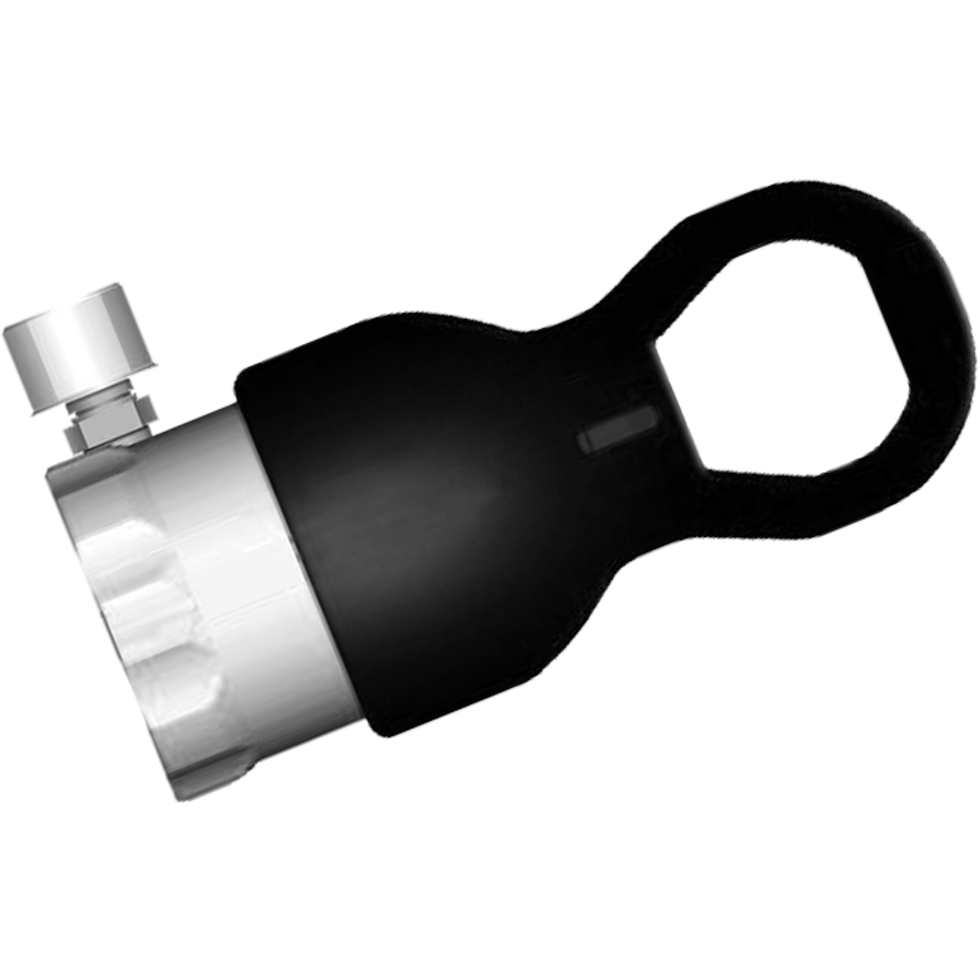

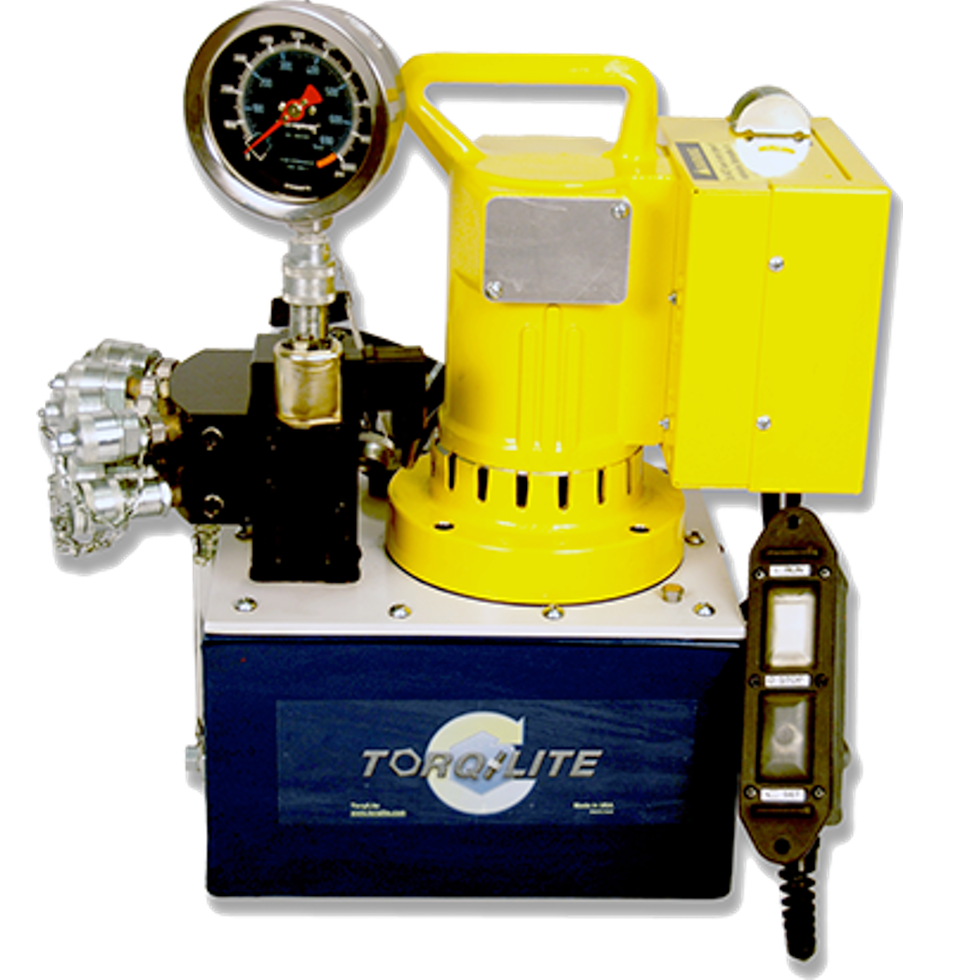

A powerful, effective pump is needed for these tools. See our pump selection to find the right pump for you.