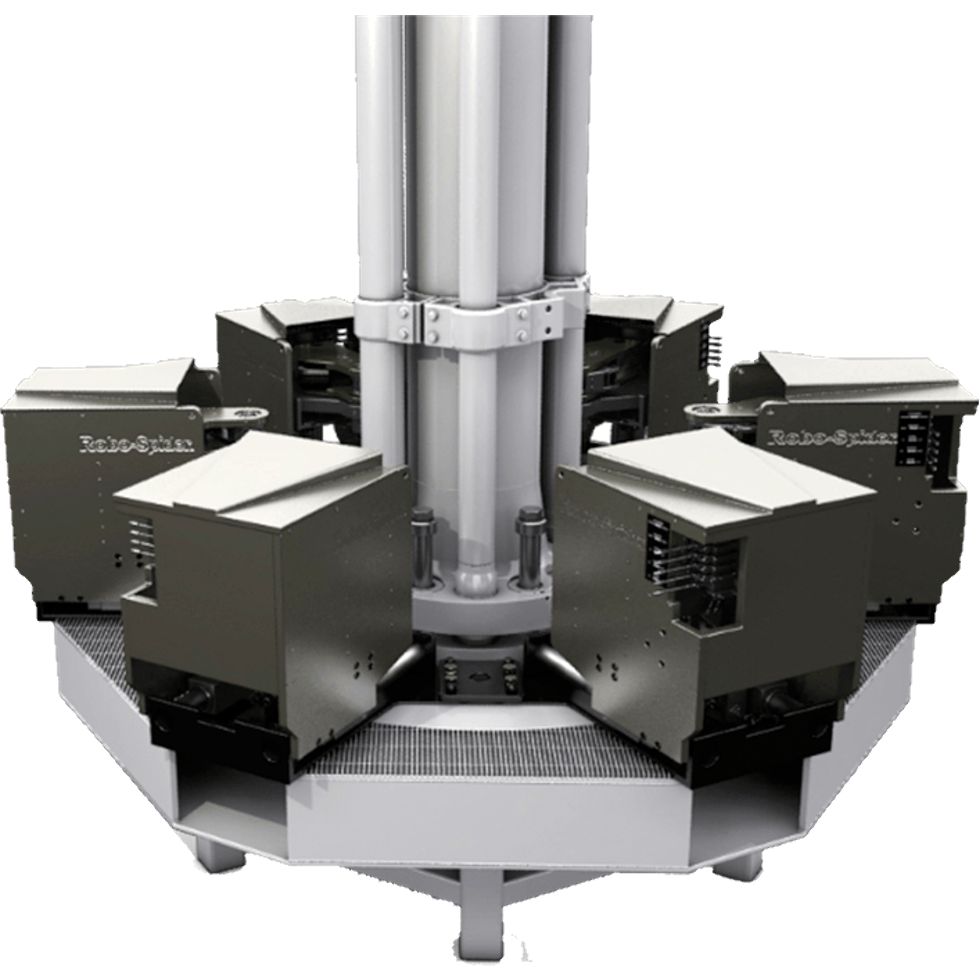

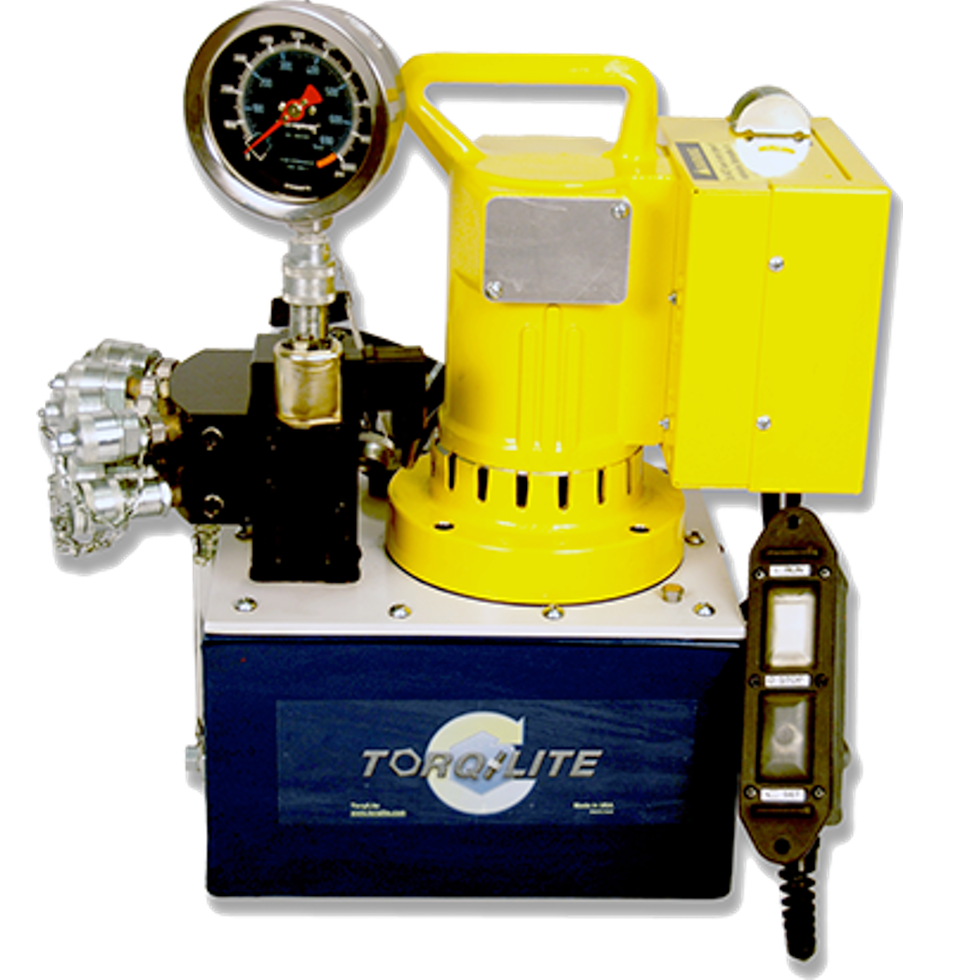

TorqLite has a variety options available for fast, safe results.

TorqLite offers highly effective flange maintenance tools. From flange spreaders to alignment tools, our line has the right tool for your scope of work. We also offer valve change-out tool sets and nut splitters to address any job situation you need to tackle.

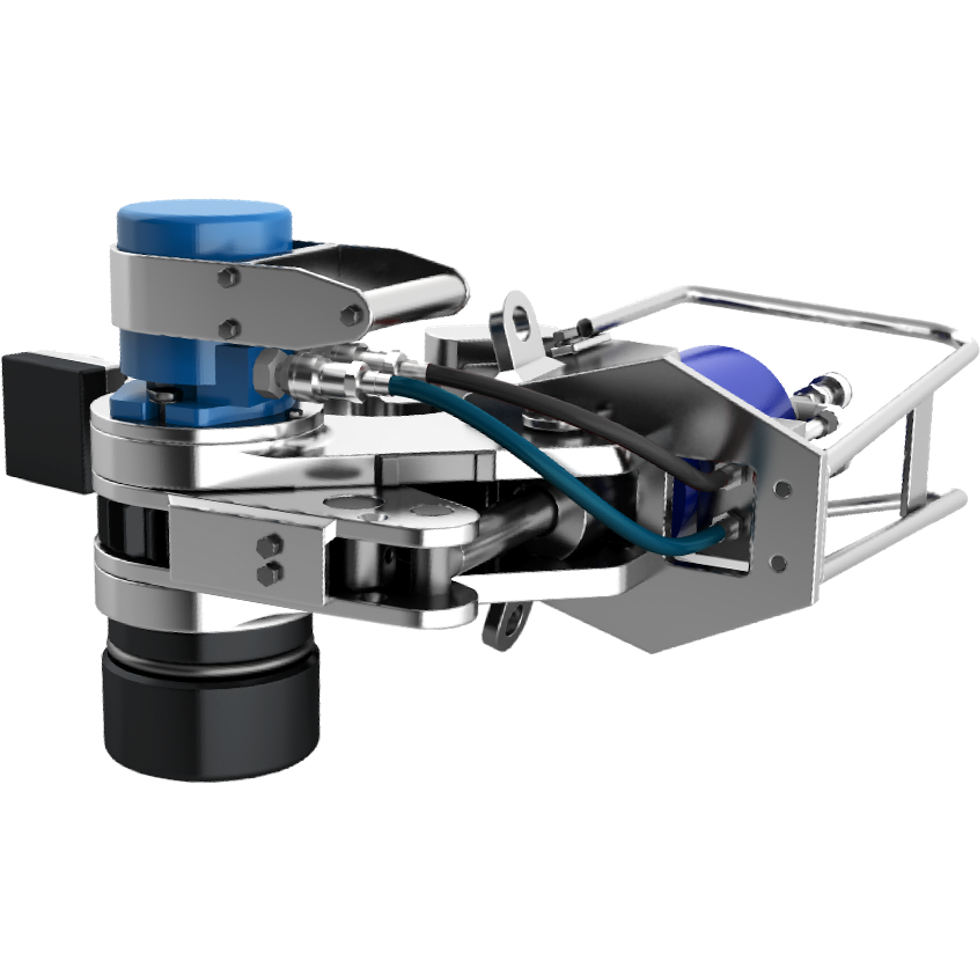

TorqLite flange alignment tools help ensure accurate positioning.

Our flange alignment tools effectively correct twist and rotational misalignment without additional stress in pipelines. We also offer hydraulic cylinders, jacks, and lifting wedges to assist in optimal positioning and alignment.

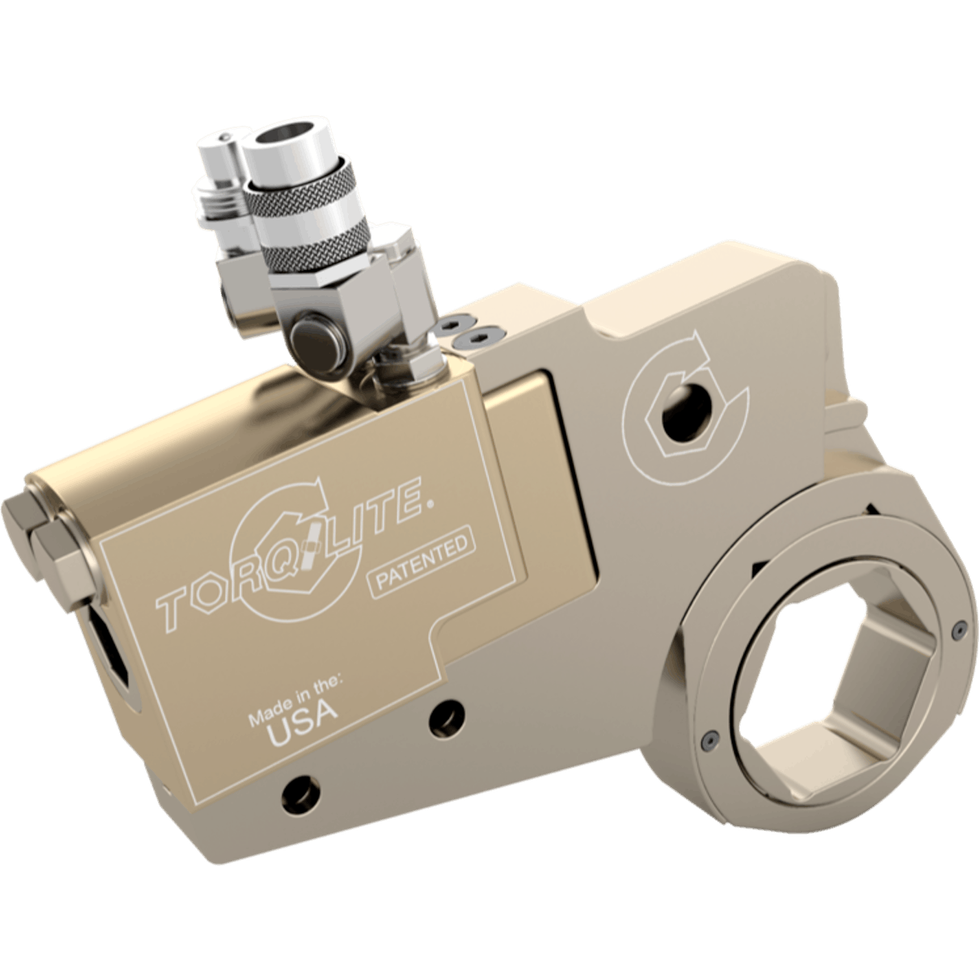

TorqLite offers both hydraulic and mechanical Flange Spreader.

Separate small, medium, or large flange joints easily with TorqLite hydraulic or mechanical flange spreaders. We offer a variety of tools to meet your needs, depending on flange size, the access gap between the flange faces, and more.

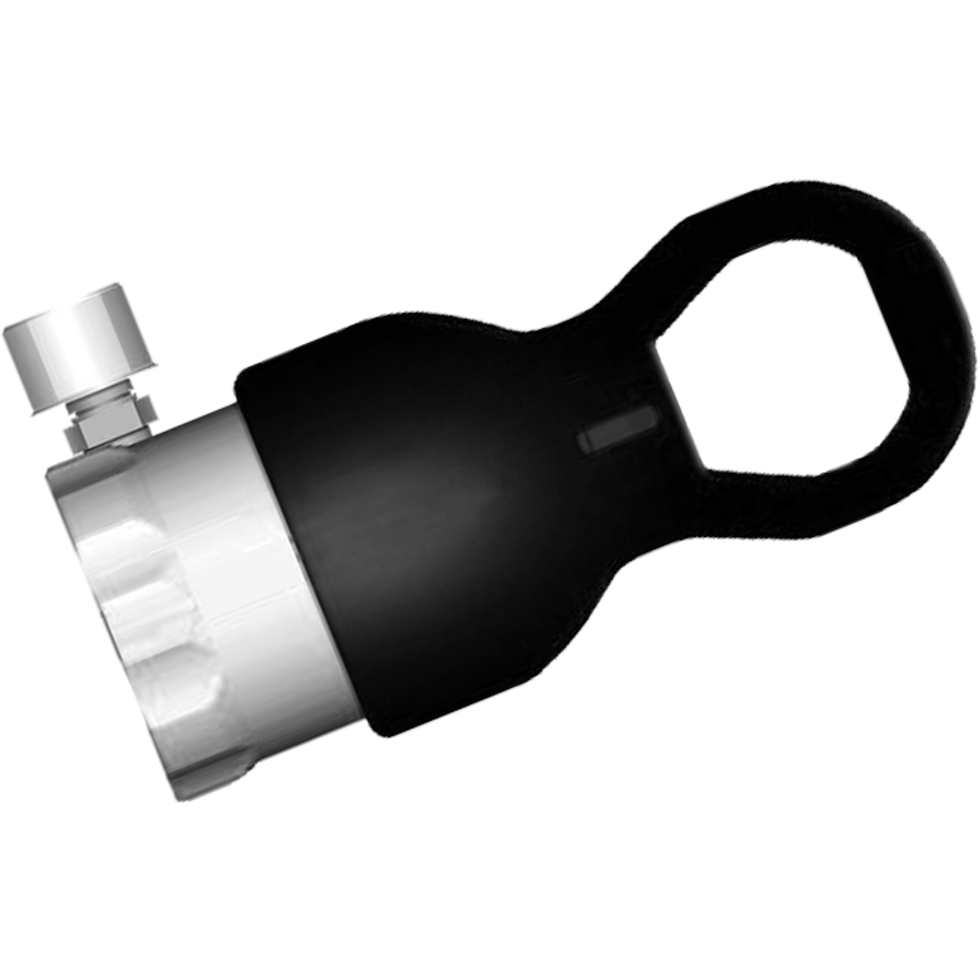

We have the valve change-out tool set and nut splitter you need.

We offer a variety of valve change-out tool sets and hydraulic nut splitters designed for ease of use that will address your job requirements. You will see noticeable improved productivity and safety with marked, calibrated systems that remove all guesswork.